-

play_arrow

Newy 87.8 FM Playing The Music You Know And Love

-

play_arrow

play_arrowJim’s Dairy Delites: Newcastle’s Historic Milk Bar SOLD and Undergoing Restoration Newy Staff

ATSB Report: King Air Makes Emergency Wheels-Up Landing at Newcastle Airport After Nose Gear Failure

today14 November 2024

newy.com.au – A Beechcraft King Air B200 was forced to perform an emergency wheels-up landing at Newcastle’s Williamtown Airport after a fatigue crack led to a nose gear failure, according to a recent report by the Australian Transport Safety Bureau (ATSB).

On 13 May 2024, the aircraft, registered VH-XDV and operated by Eastern Air Services, departed Williamtown Airport on a charter flight to Lord Howe Island via Port Macquarie. On board were the pilot and two passengers.

Shortly after take-off, as the pilot retracted the landing gear, he heard mechanical crunching noises. The red indicator lights on the landing gear control handle remained illuminated, indicating the gear was not fully retracted or locked. Air traffic control visually confirmed that the nose landing gear was only partially retracted.

Unable to extend the gear using emergency procedures, the pilot decided to hold the aircraft in a pattern for approximately four hours to burn off fuel, reducing the potential risk of fire during landing. With emergency services standing by, he conducted a successful wheels-up landing at Williamtown Airport. The aircraft sustained minor damage, but no injuries were reported among the pilot or passengers.

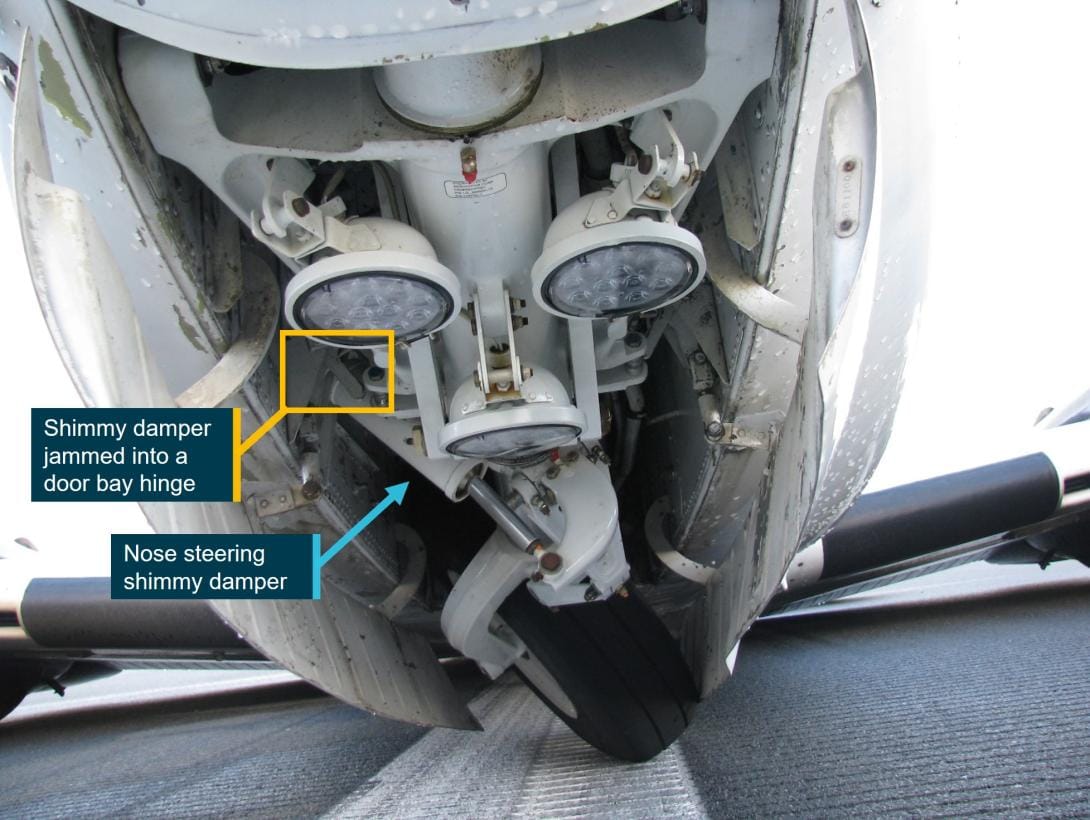

An ATSB investigation found that a fatigue crack in the nose gear steering link had fractured, causing a mechanical disconnect within the nose landing gear steering system. This failure allowed the nose wheel to rotate beyond its normal limits, causing the shimmy damper to jam against a door hinge within the nose wheel well during retraction.

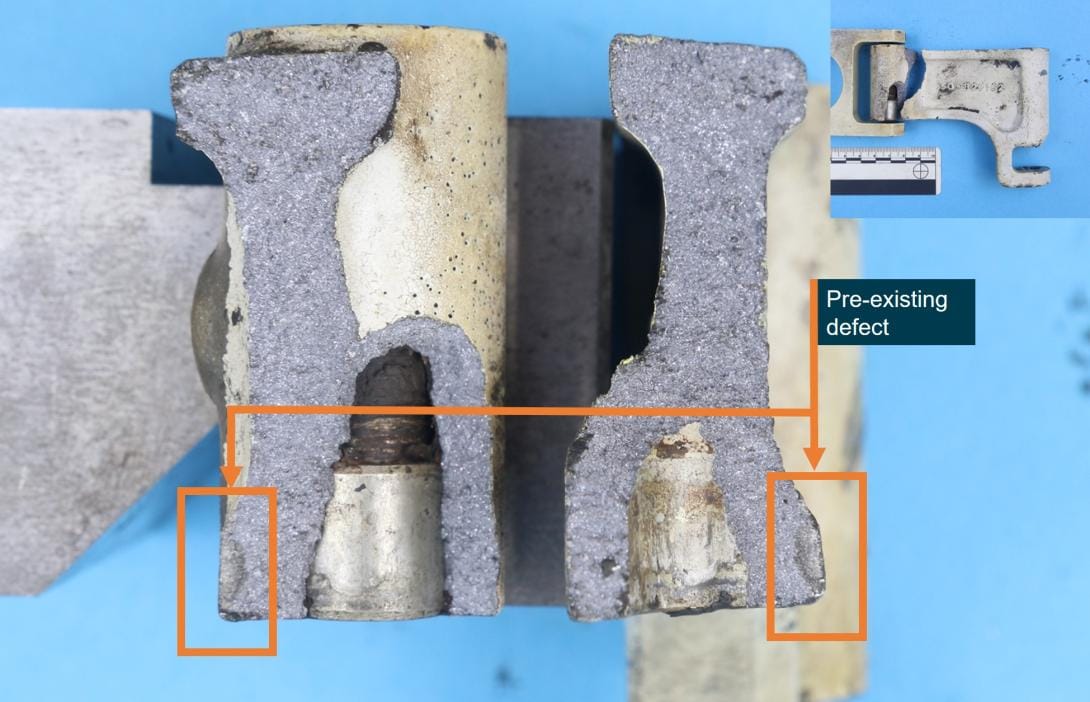

“ATSB’s detailed examination, including the use of a scanning electron microscope, identified a pre-existing fatigue crack on the steering link’s fracture surface,” said ATSB Director Transport Safety Stuart Macleod. “When the steering link fractured, the nose gear couldn’t retract properly and became jammed, preventing the pilot from extending the landing gear using the emergency procedures.”

The investigation noted that while scheduled maintenance inspections require general checks of nose wheel steering components, they do not specifically mandate detailed inspections for cracks like the one that led to this failure.

Eastern Air Services has since conducted inspections of the landing gear systems on its other King Air B200 aircraft and reported no defects. The operator is reviewing its maintenance programme to consider including non-destructive inspections of the steering link, which would be additional to the manufacturer’s existing maintenance requirements.

The aircraft manufacturer advised the ATSB that it was not aware of other instances of this specific malfunction, and a review of the ATSB’s database did not identify any similar previous occurrences involving King Airs.

Mr Macleod praised the pilot’s handling of the emergency. “The pilot managed fuel considerations to reduce the risk of fire, engaged company personnel and air traffic control for assistance, liaised with emergency services, and prepared the passengers for the wheels-up landing,” he said. “This minimised the risk of injury and ensured the evacuation was conducted safely.”

This incident offers a compelling case study in aircraft systems and emergency management. The Beechcraft King Air B200 is a twin-turboprop aircraft renowned for its versatility and reliability, commonly used in both civilian and military operations across Australia and worldwide.

The nose gear steering system of the King Air B200 is mechanically linked to the rudder pedals, allowing for direct control during ground operations. The steering link, a crucial component made from aluminium alloy, connects the rudder pedals to the nose wheel. In this incident, a fatigue crack originated from a surface flaw in the steering link, a flaw likely introduced during the casting process. Over time and under repeated stress, the crack propagated until the link fractured.

When the steering link failed, the nose wheel lost its alignment and rotated beyond its normal operational limits during retraction. This misalignment caused the shimmy damper, a device designed to prevent oscillations of the nose wheel during taxi, take-off, and landing, to jam against a door hinge within the nose wheel well. This mechanical interference prevented both normal and emergency extension of the landing gear.

The pilot’s response showcased exceptional airmanship and system knowledge. Recognising that the landing gear was jammed, he consulted the abnormal procedures but found them ineffective due to the mechanical blockage. Understanding the risks associated with a wheels-up landing, he chose to burn off excess fuel to reduce weight and minimise the potential for fire. Throughout the ordeal, he maintained communication with air traffic control, coordinated with emergency services, and kept the passengers informed and prepared.

“The pilot’s in-depth understanding of the aircraft’s systems and his methodical approach to managing the emergency were instrumental in achieving a safe outcome,” added Mr Macleod. “This incident highlights the importance of thorough pilot training and adherence to emergency protocols.”

From a maintenance perspective, the failure highlights the potential limitations of standard inspection regimes. While general inspections are conducted regularly, they may not detect subsurface flaws or fatigue cracks in critical components like the steering link. The operator’s consideration of incorporating non-destructive testing methods, such as dye-penetrant inspections, could set a precedent for more rigorous maintenance practices in the industry.

The ATSB’s investigation also sheds light on material properties and manufacturing processes. The steering link was made from cast aluminium alloy, which can be prone to porosity and surface flaws if not manufactured under strict quality controls. These imperfections can become initiation points for fatigue cracks under cyclic loading conditions typical in aircraft operations.

Join the discussion on Facebook

Join the discussion on Facebook

Written by: Newy Staff

Similar posts

Newcastle Hunter Fire Danger Rating

Search News Articles

Recent Posts

- NSW Government Declares Exclusion Zone Ahead of Rising Tide’s Planned Port Blockade 16 November 2024

- Newcastle Man Charged Over Stolen Premiership Ring 15 November 2024

- Blaze in Aberdare: Firefighters Rescue Two as House Goes Up in Flames 15 November 2024

- Major Traffic Changes Across Newcastle as Key Road and Rail Projects Surge Forward 15 November 2024

- Giant Christmas Gift Lights Up Hunter Street Mall as Newcastle’s Festivities Begin 15 November 2024

- Hunter Driver Faces Charges After Fatal Crash Near Maitland 15 November 2024

- Firefighters Tackle Ute Blaze in Caves Beach Overnight 14 November 2024

- Woman Charged in Wallsend Over Alleged Assault on Elderly Man 14 November 2024

- Man Faces Court After Alleged Copper Cable Theft Which Causes Explosion in Heddon Greta Substation 14 November 2024

- Housing Taskforce Accelerates Delivery of Over 13,000 Homes, Including Newcastle Projects 14 November 2024

- ATSB Report: King Air Makes Emergency Wheels-Up Landing at Newcastle Airport After Nose Gear Failure 14 November 2024

- Maitland’s Population is Growing By 6 People A Day, Outpacing Projections 13 November 2024

- Newcastle Lord Mayor, and Newcastle Council Support Land Based Protest 13 November 2024

- NSW Police Score Landmark Pay Deal, But Nurses Left Fighting for Wage Equality 13 November 2024

- Newcastle rail disruptions prompt hefty fines as NSW toughens stance on railway protests 13 November 2024

- Emergency Sewer Repairs to Close A15 Donald Street in Hamilton Until 23rd Nov 13 November 2024

- Hunter Region Records High Demand for Marine Rescue NSW 13 November 2024

- Lake Macquarie to Benefit 15.4 Million In Roads Funding From Federal Government 13 November 2024

- New Designs Unveiled for Maitland’s State-of-the-Art Mental Health Rehabilitation Facility 12 November 2024

- Magnitude 4.1 Earthquake Shakes Upper Hunter Region, Felt Across Multiple Suburbs 12 November 2024

Newy 87.8 FM is an FM radio station established in 2014 targeting Classic Hits music enthusiasts across Newcastle and The Central Coast, Australia. The station plays 60s 70s and 80s music. The station can be streamed online via this website or smart phone apps such as Tunein. In 2024 we opened a local newsroom dedicated to publishing Newcastle News.

© 2024 Newy 87.8 FM | Newcastle NSW Australia